Industrial Rubber Rollers are changing the fate of a variety of manufacturing industries with their unique features, properties, and applications. The emergence of innovative technology is helping industrial rubber roller manufacturer to design, manufacture, and supply a quality-driven range of industrial rubber rollers.

Unique properties of industrial rubber rollers

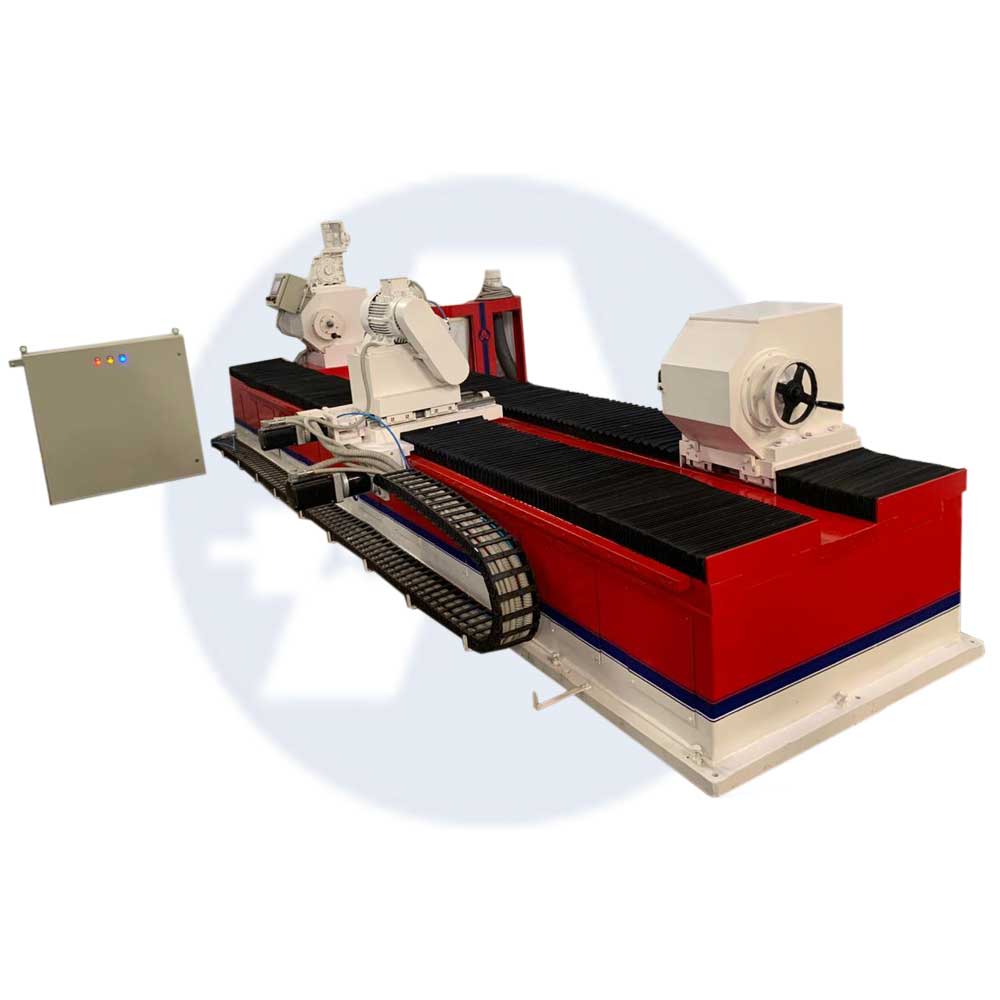

Precision-driven industrial rollers are recognized for demonstrating a variety of properties, including the least maintenance, sturdy design, durability, ease of installation, resistance to harsh weather conditions, high tolerance, etc.

From the basics, let’s now shift our focus toward other core subjects of this short blog.

Applications of rubber roller

Industrial rubber rollers are installed in a variety of manufacturing setups for various applications, including Gravure printing, Flexographic printing, Solventless lamination, Adhesive coating, Blown film line, Palletize machine, Squeezing materials, and Removing wrinkles from the film among others.

The quality product assumes significance in this era of tough business competition. For detailed information, you can connect with a leading industrial roller company with vast experience in the field.

Industrial use

Rubber Roller company manufactured rubber rollers are being used on a large scale, in a wide range of industries, including Paper, Plywood, Tyre, Steel, Packaging, and Textile among others.

A few industrial rubber roller manufacturers in Ahmedabad hold professional expertise to deliver customized solutions. Backed by their professional expertise and modern technology, they deliver rubber roller as per the client’s specifications, like length and diameter.

Before jumping to any conclusion and placing an order for a rubber roller, we recommend you validate the credibility of the industrial rubber roller manufacturer company.

in case, you are searching for a reputed rubber roller company in Ahmedabad, don’t forget to connect with Arvind Rub-Web Controls Pvt. Ltd.